Soundproof Louver

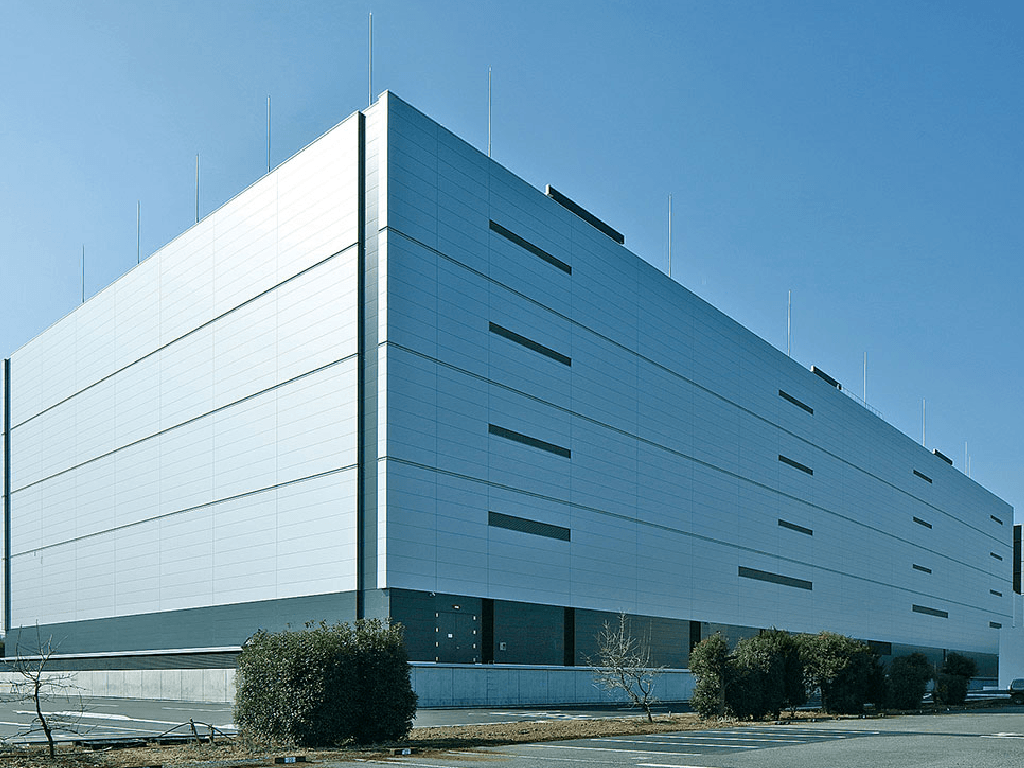

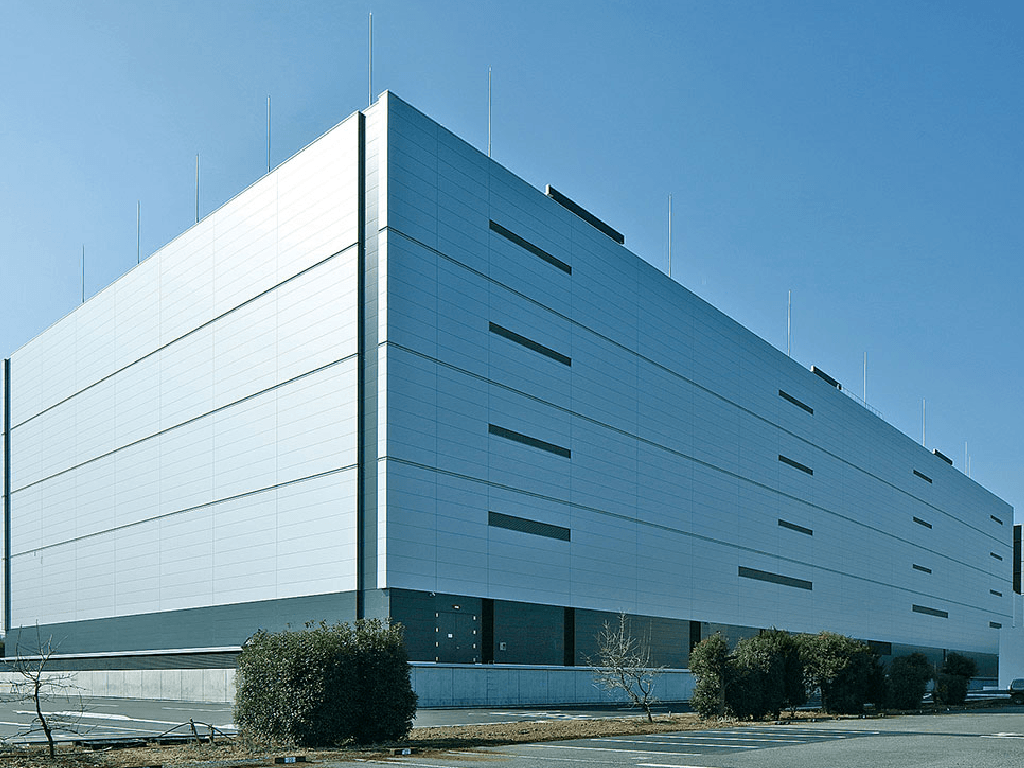

This advanced soundproofing louver system is designed to withstand wind pressures of up to 4000 N/m² and is suitable for harsh environments. The mounting width is up to 5 meters, which provides versatility in architectural design.

The most important feature is the large mounting aperture ratio, which effectively attenuates external noise and achieves excellent soundproofing performance. The system promotes efficient ventilation, improves indoor air quality, and reduces reliance on mechanical ventilation systems for energy efficiency.

Structurally, it incorporates a rainwater diversion mechanism to ensure durability and protection from water-related damage. Aesthetically, the sleek design with smooth curved surfaces enhances the appearance of the building, creating a comfortable indoor environment with minimal reflection of sunlight. Overall, the system offers an excellent solution for optimal interior comfort, sustainability and design.

This system provides excellent solutions for indoor comfort, sustainability, and design.

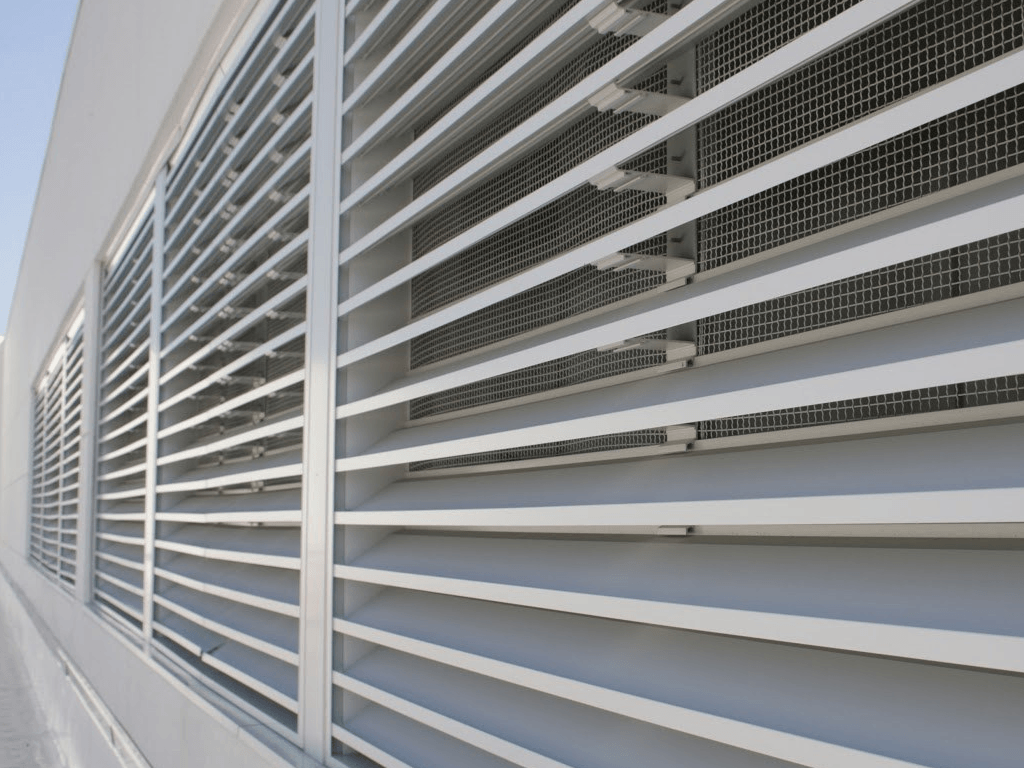

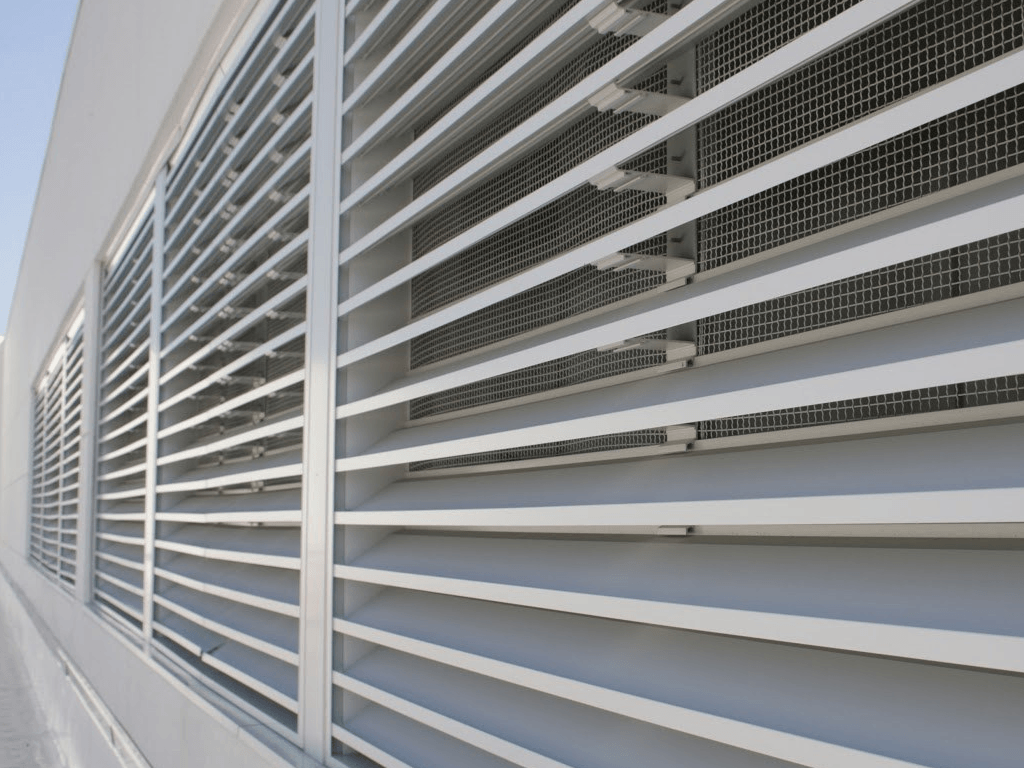

- Acoustic louvers

Acoustic louvers are designed to significantly reduce noise. It uses a strategic blade configuration and sound-absorbing materials to form an acoustic barrier. In addition, baffles and perforated panels have been incorporated to enhance sound insulation. We use CFD simulation and acoustic modelling technology to achieve both noise reduction and ventilation efficiency.

- Acoustic louvers for architectural applications

These louvers blend acoustic isolation with a beautiful design, damping sound waves while maintaining an appearance. Based on the principles of building acoustics, it is precisely designed to minimize sound transmission. Advanced manufacturing techniques allow for intricate details and customization, optimizing functionality and design integration

Soundproofing panel

Soundproofing panels in architecture are an essential element to be acoustically comfortable and promote productivity, relaxation or concentration activities. These panels are designed to reduce noise by absorbing, diffusing, or blocking sound, improving the overall sound quality in the building.

A type of common soundproofing panel is made of acoustic foam or a material wrapped in fabric. These panels are used in recording studios, auditoriums, offices, residential spaces, etc., to reduce reverberation and minimize sound transmission between rooms. They come in a variety of sizes, shapes, and colors to ensure that they can be seamlessly integrated into the overall aesthetic of the building.

Another type of soundproofing panel is double-glazed windows. It consists of two panes of glass separated by layers of air and gas. This design greatly reduces outdoor noise penetration and retains natural light and views. Double-glazed windows are popular in urban environments and areas with high noise pollution levels.

The average noise reduction achieved by quality soundproofing panels is usually in the range of 20 to 30 decibels (dB):

- 20 dB reduction: This level of noise reduction is about the same as the difference between whispering and normal conversation, or the volume in a quiet library.

- 30 dB reduction: This level of noise reduction reduces the noise of traffic to background rustling, making a clear difference in noisy environments.

Torsional louvers

With its distinctive and innovative design, the twisted louvers provide a multifunctional solution for managing environmental elements in a space. The detailed explanation is as follows.

Twist louvers are architecturally precision designed to incorporate angled slats and fins that can be twisted and rotated along a longitudinal axis. This dynamic feature gives occupants granular control over airflow, light transmission, and privacy in their environment. Louvers allow the slats to be adjusted to different angles, meaning you can fine-tune the balance between natural lighting and glare reduction, or regulate air circulation while minimizing energy loss.

The design of twisted louvers is not only functional, but also aesthetically pleasing, contributing to the visual dynamics of the façade and interior design scheme of the building. It can be seamlessly integrated into modern, minimalist, and even industrial styles, enhancing the overall look while providing practical benefits.

Twist louvers can be operated manually and individually adjusted, or mechanically integrated into a building's automation system for centralized control. This adaptability makes it suitable for a wide range of applications, from residential to commercial environments where the regulation of environmental factors is essential.

- Features and design of twisted louvers.

- A fusion of aesthetics and functionality.

- Flexibility and adaptability of operation.

Chamber Box

An air plenum box is a critical component of an HVAC system that is used to evenly distribute air in residential, commercial, or industrial locations. Mainly made of galvanized steel or aluminium, this box acts as a central concentrator that directs air from the main ductwork to the various outlets. It has a customizable design to suit architectural or spatial requirements and includes features such as insulation to minimize noise and heat loss, as well as dampers to control air flow.

The interior of the box is typically lined with sound-absorbing materials to further reduce noise levels. The effect of the air plenum box lies in maintaining consistent air pressure in all connected vents and ensuring efficient airflow, which contributes significantly to the energy efficiency and comfort of the entire building. Its installation is direct and designed to integrate seamlessly into existing ductwork, making it an essential yet discreet component in modern HVAC systems.

- Features of the air plenum box.

- Customizable design and additional features.

- Contribution to energy efficiency and comfort.

Custom-made extrusion molds

Custom extruded materials are manufactured through an extrusion process in which the material is extruded through a die to create an object with a fixed cross-sectional shape. This method is popular due to its efficiency and versatility, allowing it to produce long pieces with complex geometries.

The materials used in extrusion are diverse, ranging from metals such as aluminium, steel, copper, and brass to plastics such as PVC, polyethylene and polystyrene, and even composites. Each material is selected based on the desired properties of the final product, such as strength, flexibility, corrosion resistance, or thermal stability.

When it comes to shape, extruded materials can take almost any shape that is designed into a die. Common shapes include tubes, rods, beams, and a variety of custom profiles that are elaborately designed to meet specific functional requirements. These profiles are an important part of a wide range of applications in the construction industry, as structural components, as frames and rails in automotive manufacturing, and in consumer products.

- Efficiency and versatility of the extrusion process.

- Use of diverse materials.

- Diverse shapes and applications.

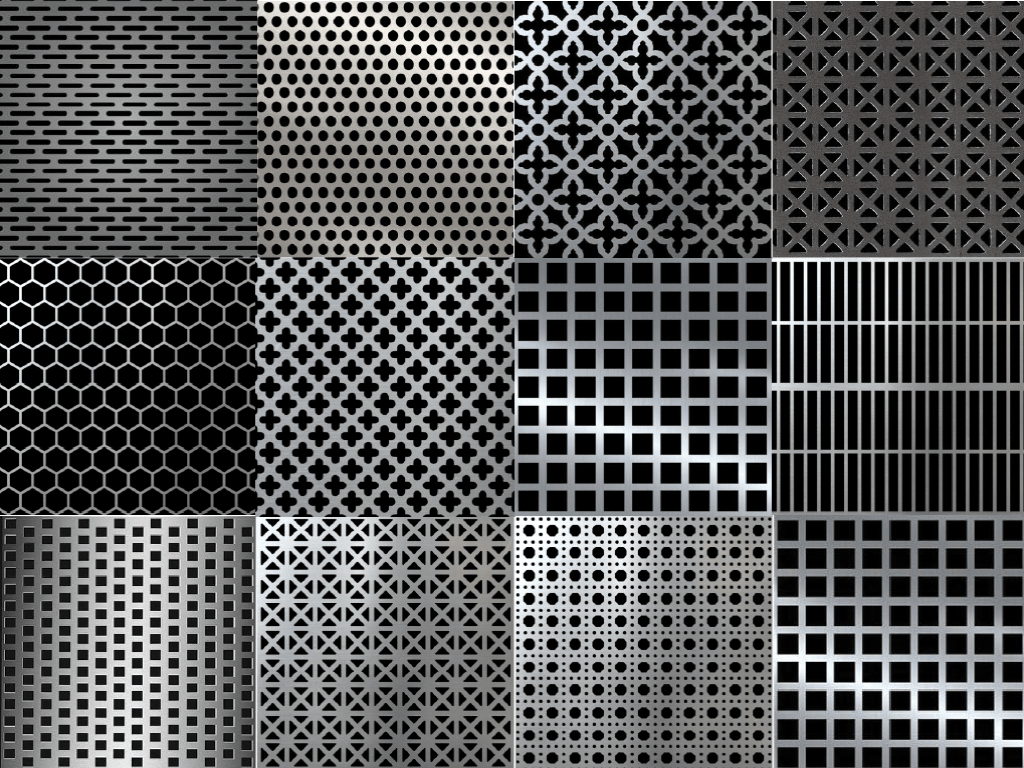

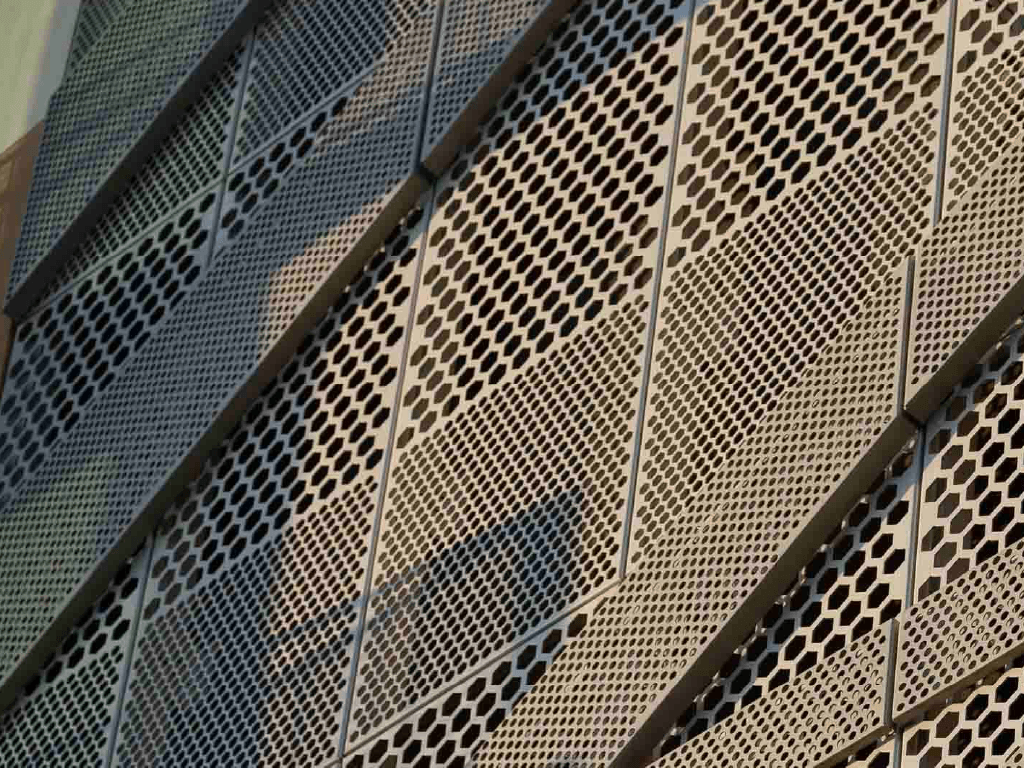

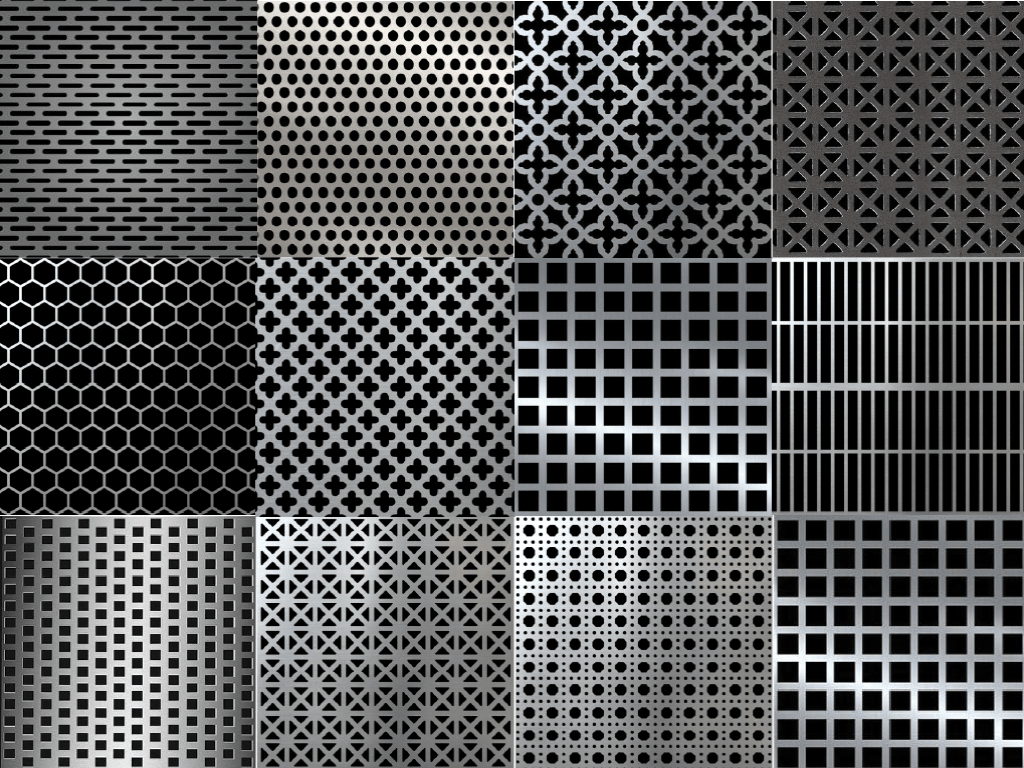

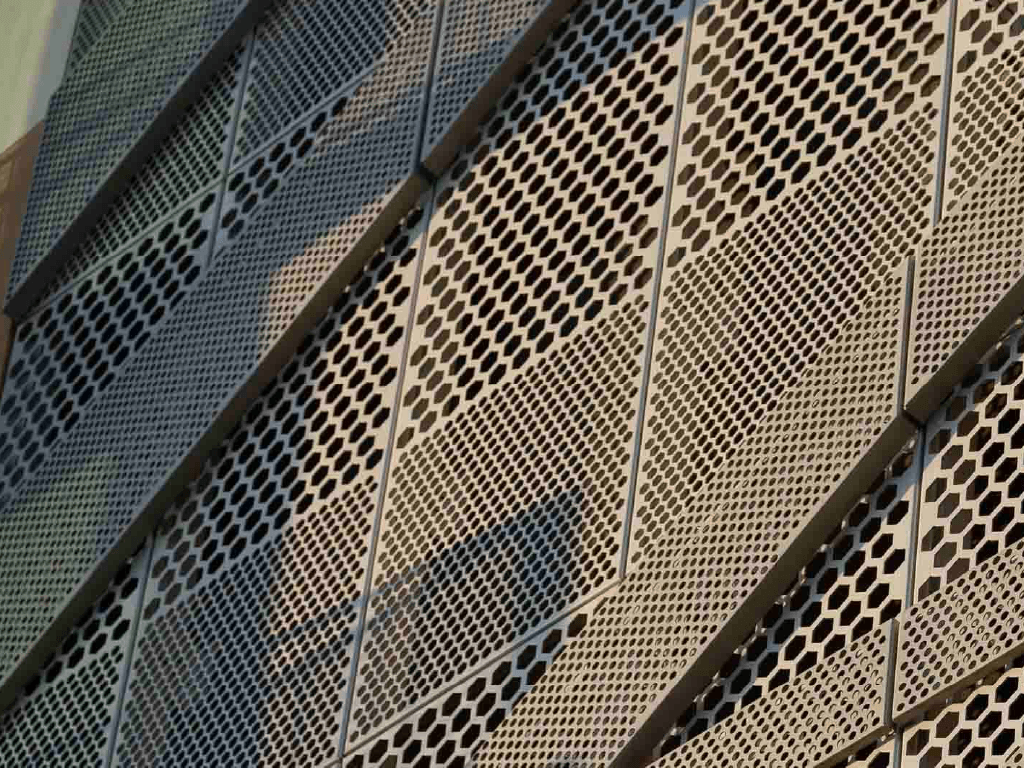

Expanded metal

Expanded metal panels are made by cutting and stretching metal sheets to form a mesh structure with a distinctive diamond-shaped pattern. These panels can be manufactured in a variety of metals, including aluminium, steel, stainless steel, and titanium, depending on their strength, aesthetics, and corrosion resistance needs. It is mainly used as a decorative feature of architectural facades and cladding, providing functional benefits such as ventilation and light diffusion, while also providing visual appeal. Its robustness also makes it ideal as a safe fence or barrier in residential and industrial facilities.

In industrial environments, it is also used for non-slip sidewalks, catwalks, and safety applications as a grate. It is also sometimes used in filter systems in the automotive and agricultural industries and is chosen for its permeability. Panels are available in a variety of thicknesses and gauges, and sizes and shapes can be customized to suit specific installation requirements. To increase durability and match aesthetic preferences, finishing options such as galvanizing, powder coating, and painting are available. This makes extended metal panels a versatile option.

- Expanded metal panel construction and manufacturing.

- Both decorative and functional.

- Wide range of applications and customizability.

Wire Mesh

Wire mesh is widely used in demanding environments such as zoos, safaris, marine parks, and other wildlife reserves. Manufactured from high-quality imported stainless steel wire, this product is chosen for its durability and aesthetic refinement in architectural projects.

Produced using an advanced manufacturing process that combines cutting-edge technology with skilled craftsmanship, wire mesh stands out in the market as a professional and exclusive product. It is designed to be both functional and visually appealing, offering excellent structural integrity and a refined finish.

It also provides excellent resistance to rust, corrosion, and environmental wear, making it ideal for both indoor and outdoor applications. The mesh's flexibility allows it to be easily shaped and customized for creative and complex architectural designs.

Additionally, wire mesh is environmentally friendly and long-lasting, requiring minimal maintenance or replacement while offering sustained performance and beauty.

- Wire mesh.

- High-quality materials and technology.

- Flexibility and environmental consideration.